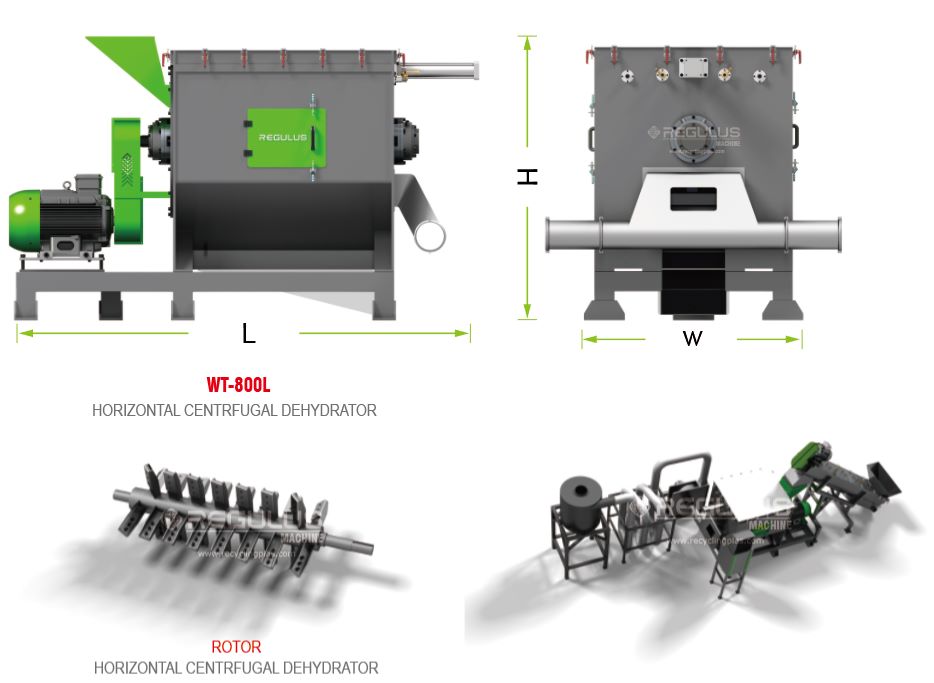

Wet PP PE Pet Flakes Bags Plastics Centrifugal Dewatering Dehydrator Dryer Machine

Plastics Horizontal Centrifugal Dehydrator Dewatering Machine

The horizontal centrifugal dehydrator is mainly used for the film dehydration process in the plastic recycling and washing line. It can quickly and effectively remove moisture from the washed film or flakes, thereby shortening the subsequent drying time, reducing energy consumption, and improving overall production efficiency.

Washing the material with high speed to remove water, the material final moisture is below 2%. It is mainly appied in plastic recycling line.

Application:

| soft plastics | PE, PP, HDPE, LDPE, LLDPE greenhouse film, agricultural film, packaging bags, ton bags, woven bags, plastic lawn and other soft flakes. |

| hard plastics | plastic lumps, plastic bottles, plastic containers, plastic blue barrels and other rigid flakes |

Suitable for:

Advantages:

High quality and durable

The whole is made of 304 stainless steel. Possess excellent corrosion resistance and mechanical strength. The equipment has a smooth surface and excellent anti-oxidation performance, making it easy to clean and maintain daily. Significantly extends the service life of equipment and reduces long-term operating costs.

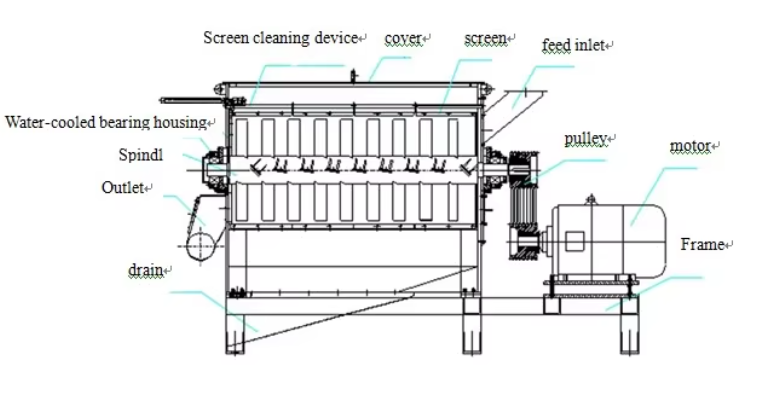

Precision rotor design, smooth operation

The rotor is dynamically balanced to ensure that the equipment remains stable at high speeds and to reduce vibration and noise. The precise design of the rotor not only improves the dehydration efficiency, but also significantly enhances the operational reliability, providing a guarantee for efficient production.

Efficient dehydration, easy disassembly

The built-in removable dewatering screen is easy to replace and clean quickly, effectively preventing equipment blockage due to material residue. The equipment has extremely high dehydration efficiency, which can significantly reduce the moisture content of the material, saving drying time for subsequent processes and increasing output. Efficient performance and stable working conditions provide enterprises with continuous and reliable production capabilities.

Water-cooled bearing seat, durable

The bearing seat adopts a water-cooling structure design. It can quickly dissipate heat, effectively control the operating temperature of the bearing, and avoid equipment loss caused by overheating. This design greatly extends the service life of the bearings, reduces maintenance frequency and downtime, and further improves the overall operation stability of the equipment.

Convenient operation and maintenance

The unit is equipped with an easy-to-open top cover, allowing operators to quickly inspect or clean internal components. The flexible structural design not only simplifies the operating process, but also greatly improves the efficiency of daily maintenance, thereby improving the working efficiency of the overall production line.

Compact structure and stable performance

The horizontal design makes the equipment more stable during operation. At the same time, the optimized internal structure and high-quality material selection ensure the durability and service life of the equipment.

Paraments:

| Model | WT-650 | WT-800A | WT-800B | WT-800C |

| Rotor diameter(mm) | 650 | 800 | 800 | 800 |

| Main motor power(kw) | 37-45 | 75 | 90 | 110 |

| Main shaft speed(r/min) | 1450 | 1450 | 1450 | 1450 |

| Capacity(kg/h) | 300±50400±50 | 500-700 | 650-900 | 800-1100 |