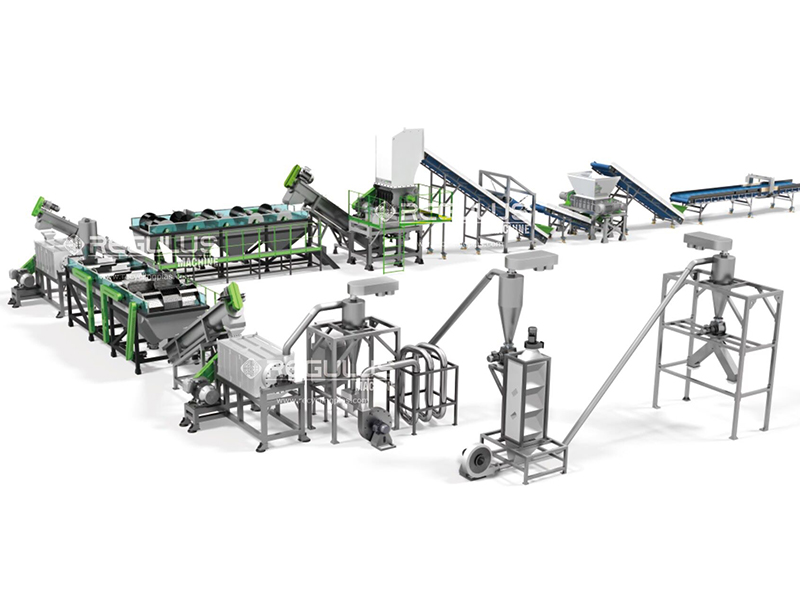

Plastic Washing Recycling Line

Plastic Washing Recycling Line Plastic Granulating Recycling Line

Plastic Granulating Recycling Line Shredder And Granulator

Shredder And Granulator Plastic Squeezing Dryer Pelletizer

Plastic Squeezing Dryer Pelletizer Plastic Agglomerator

Plastic Agglomerator Other Plastic Machine

Other Plastic Machine

Products

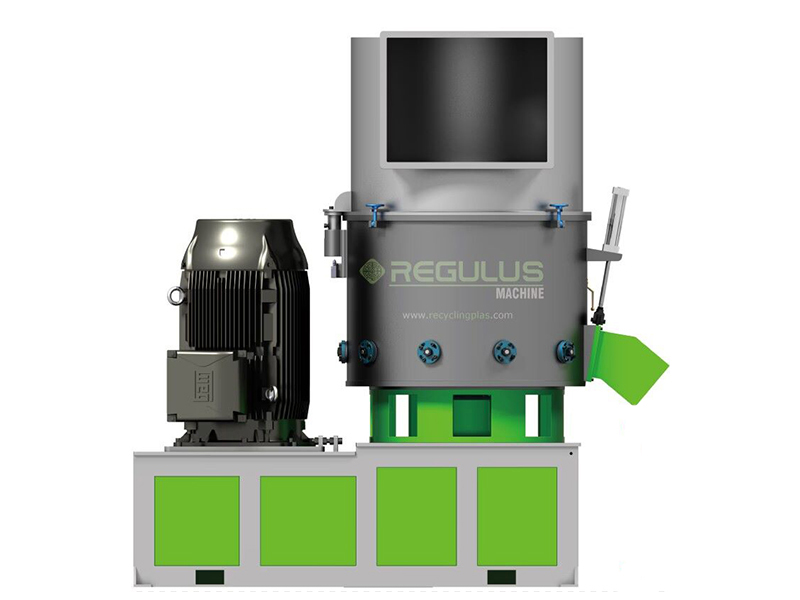

PLC Control Automatic Plastic Agglomeration Recycling Machinery

The Agglomerator machine can directly make plastic material into granules. Agglomerator machine can dry plastic and reduce plastic material humidity. Agglomeration machine can improve the quality of your product, increase your machine output, and increase your profit. The agglomeration machine can be used for a wide range of raw materials, such as plastic PE film, HDPE foil, LDPE film, PE bags, PP woven bags, PP non-woven, PP raffia, plastic sheet, flakes, fiber, PA nylon, PET Fabric & Fiber textile material, and other plastics.

Plastic Film Agglomerator

Agglomeration, drying, re-crystallization, compounding.

It is suitable for plastic PE, HDPE, LDPE, PP, PVC, PET, BOPP, film, bags, sheet, flakes, fiber, nylon, etc.

Model: from 100kg/h to 1500kg/h.

This machine can produce pellets for direct extrusion machines, film blowing machine, injection molding machine, and also can be feed into extruder granulating plasticizing line for making granules.

Blade Sharpener

The machine is specially designed for crusher blades, granulator blades, agglomerator blade, bag making machine blade; it can greatly raise working efficiency as well as grinding woodworking and other machinery flat blade.

Plastic Mixer Dryer

Regulus’s mixer dryer is designed as a two-stage spiral conveyer. The first stage quickly feeds the raw materials into the barrel, and the second stage continuously raises the raw materials to the upper end of the barrel. The hot air flows from the center of the lower part of the barrel. It is blown to the surroundings, and the dynamic process of comprehensive heat exchange is penetrated smoothly from the gap of the moving raw material to the bottom. As the materials are constantly tumbling in the barrel, the hot air is continuously conveyed from the center to achieve the mixing and drying simultaneously, saving time and energy. If you do not need a dryer, you need to turn off the hot air source and use only the mixing function. Suitable for mixing granules, crushed materials and masterbatches.

Plastic PE PVC Pulverizer Machine

The automatic plastic mill is disk-type plastic pulverizer, which has the advantages of high capacity and low-power, This machine can be used for powder processing of PE, HDPE, PP, PS, ABS, EVA, PET, nylon and other materials.

Industrial Chiller

Industrial Chiller has air cooled industrial chiller and water cooled industrial chiller. It is widely applied in small-medium scale industrial cooling, helping to accurately control the temperature during processing, increase the product quality and improve the production efficiency.

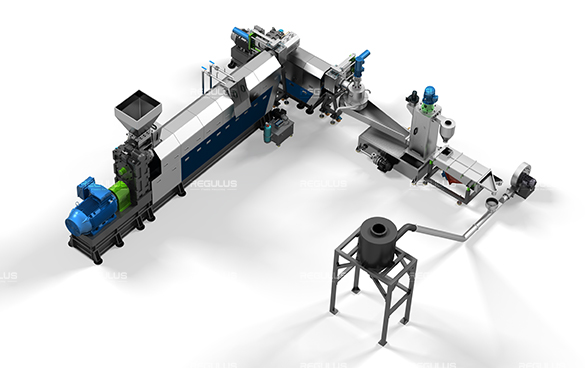

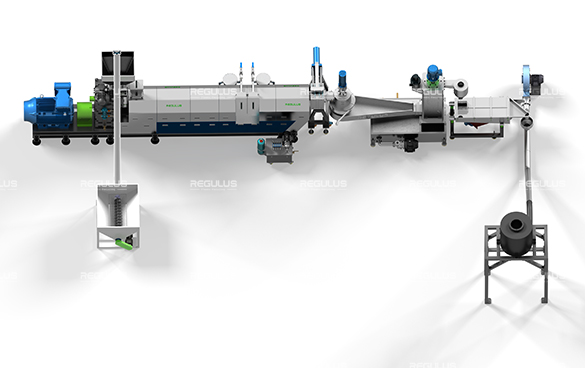

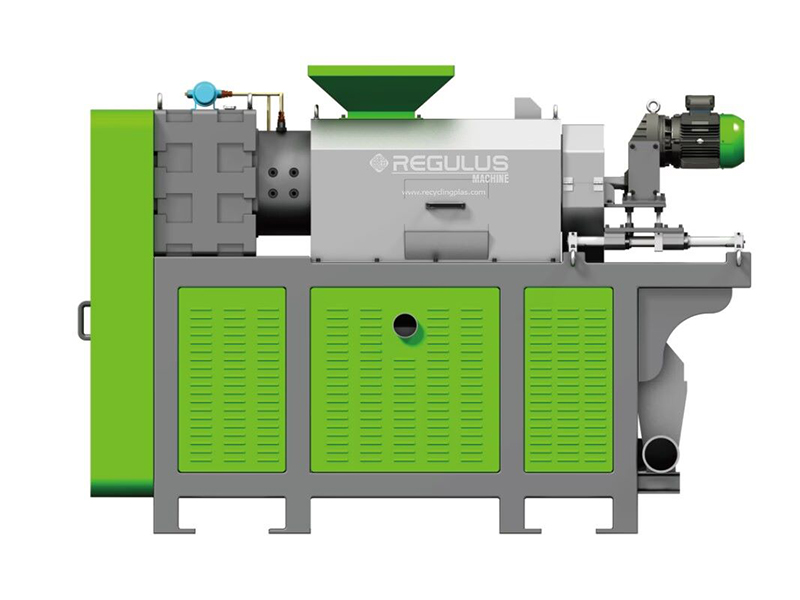

Double Stage Cutter Compactor Recycling Pelletizing Line

Double Stage Cutter Compactor Recycling Pelletizing Line

Single Stage Cutter Compactor Recycling Pelletizing Line

PE PP PET film compaction bin recycling and granulation line

Film recycling

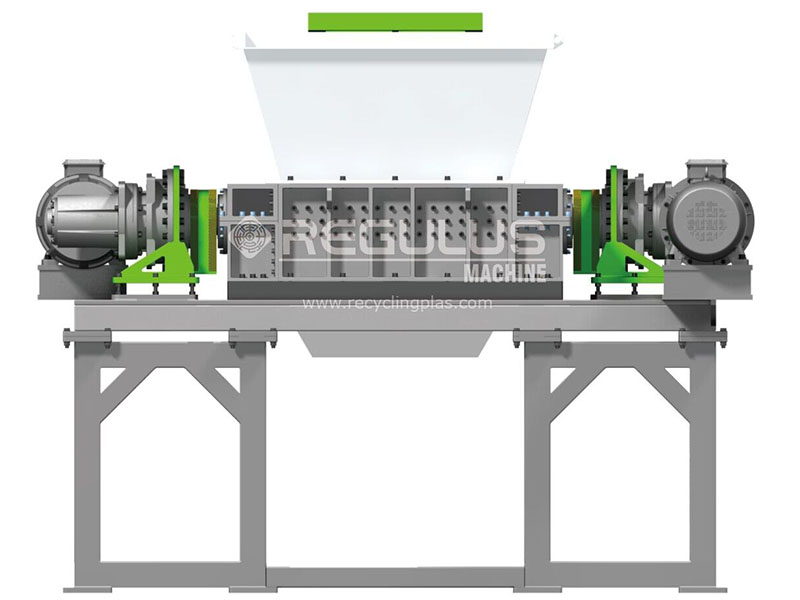

Swing arm Singls Shaft Shredder

The swinging arm shredder which uses gravity to guide material onto the shaft. Suitable for processing a wide range of materials including: plastic bales, jumbo bags, plastic barrel, plastic lumps, Refrigerator, Pipe, Tires, Washing machine, Copper, Aluminum, Pallets

Plastic Shredder and Granulator 2 in 1 Machine

Single shaft shredder and granulator are built together. Waste plastic shredder and crusher in one machine has two parts in one machine. The first part is shredding part on the top. The second part is crushing parts, which is under the shredding part for fine crushing. End product is 8-16mm particle materials. After shredding, the shredding material goes into crusher machine directly. Through this shrdedding crushing 2-in-1 machine, customer no need to buy belt conveyor between shredder and granulator, so it can save cost and save space.

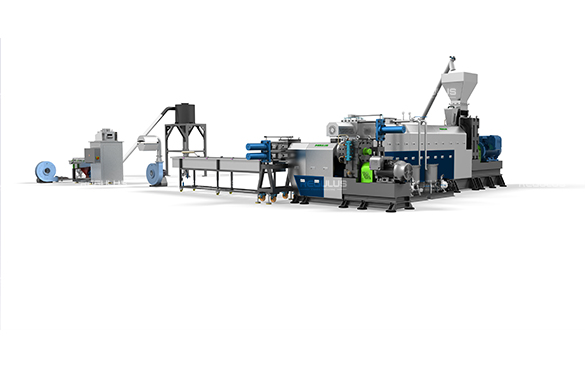

Single screw extruder recycling machine

Single screw extruder recycling machine

Double stage strand cooling plastic pelletizing line

Double stage strand cooling plastic pelletizing line