Plastic Washing Recycling Line

Plastic Washing Recycling Line Plastic Granulating Recycling Line

Plastic Granulating Recycling Line Shredder And Granulator

Shredder And Granulator Plastic Squeezing Dryer Pelletizer

Plastic Squeezing Dryer Pelletizer Plastic Agglomerator

Plastic Agglomerator Other Plastic Machine

Other Plastic Machine

Products

Wet PP PE Pet Flakes Bags Plastics Centrifugal Dewatering Dehydrator Dryer Machine

Plastics Horizontal Centrifugal Dehydrator Dewatering Machine The horizontal centrifugal dehydrator is mainly used for the film dehydration process in the plastic recycling and washing line. It can quickly and effectively remove moisture from the washed film or flakes, thereby shortening the subsequent drying time, reducing energy consumption, and improving overall production efficiency. Washing the material with high speed to remove water, the material final moisture is below 2%. It is main...EPS Plastics Granulating Pelletizing Line

The plastic granulation and recycling production line is an industrial equipment used for plastic waste recycling and reuse. It is an integrated system that converts plastic waste into usable pellets that can be used to produce new plastic products.

High Quality EPS Foam Recycling Hot Melting Plastic Recycling Machines

The EPS foam hot melting machine compress foam by screw heating melting extrusion way, then make the foam scraped into an EPS foam compression blocks. After compaction, the waste Styrofoam can be reused to make other products, such as frame products and construction moldings.

PA PC PET Crystallization Dehumidification Drying Equipment

The Dehumidifying dryer combine dehumidifying and drying system into a single unit. This machine has many applications in processing plastic materials, such as PA, PC, PBT, PET.

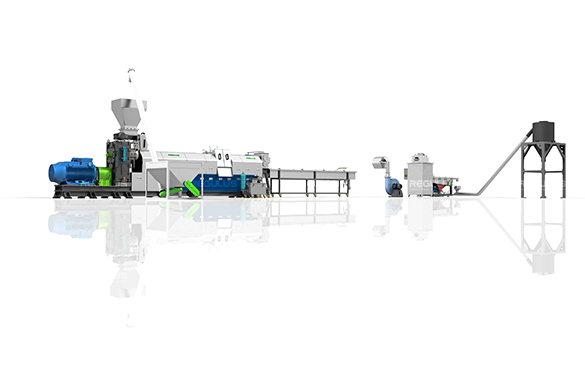

Single screw strand cooling granulation production line

Single screw strand cooling granulation production line

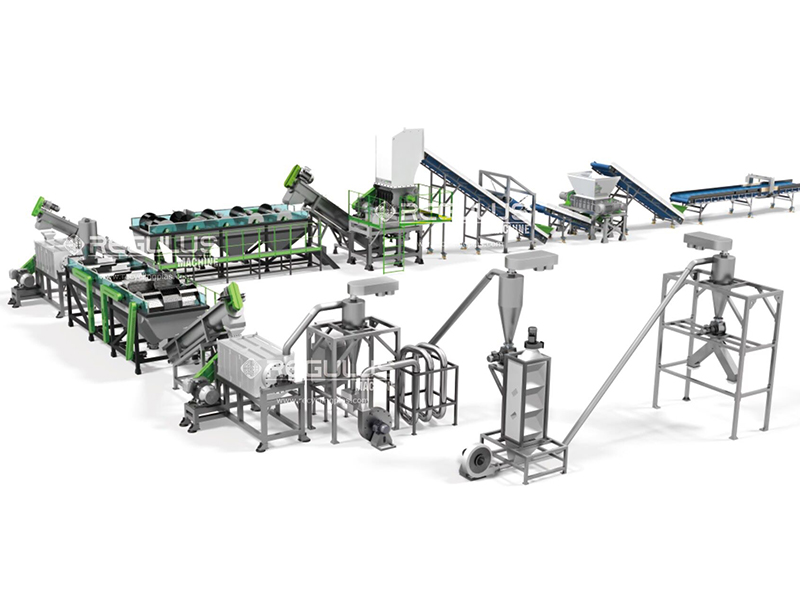

PE PP Washing and Recycling Line

PP, PE film washing and recycling line is mainly consist of the following machines: Belt conveyor, metal detector , crusher, screw feeder, high speed friction washer, floating washer, dewatering machine, drier, storage silo and control cabinet.

Post-consumer PET Bottles Washing And Recycling Line

PET bottle flake washing line is a series of equipment used to clean and process post-consumer PET bottles into clean, recyclable PET bottle flakes.

High Efficiency PET Washing Recycling Line 500-6000kg/h

Our Regulus company has a long experience in the field of PET recycling, we offer state-of-the-art recycling technologies, with turn-key installations having the widest range and flexibility in production capacity (from 500 to over 6.000 Kg/h outputs).

PE PP Plastic Scraps Crusher Washer Dryer Granulator Machine

Usage: It is used for cleaning the waste dirty plastic scraps, such as film, agricultural film, woven bags, non-woven, bottles, barrel, drum, box, chairs.

Structure: The complete line includes shredder, crusher, and washer, dryer.

Model:300kg/h-2000kg/h

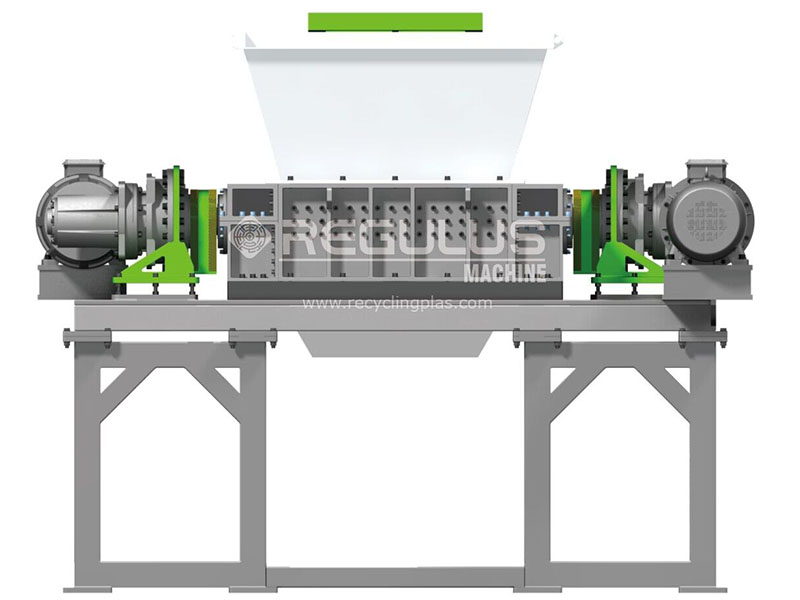

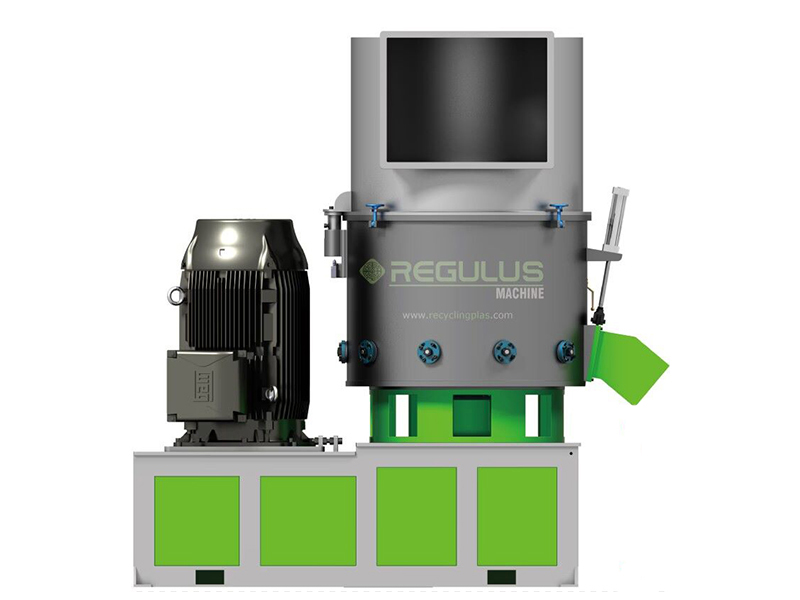

Double Shaft Shredder

Regulus brand shredder is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, fiber, rubber, organic waste and a wide variety of materials.

Two-roller Shredder for Plastic film and PP ton bags

Single and Two shaft shredders adopt double film shafts design that rotate a medium speed, low noise and high efficient without pusher. Adopt SIENMENS brand microcomputer control system with function of start, stop, automatic reverse sensors to protect the machine against over loading and jamming. It is especially suitable for recycling the medium hardness and soft material, for example PE film, LDPE film, HDPE bags, PP woven bag, PP jumbo bag, paper and ect. Aiming at different material, machine could use different shaft.

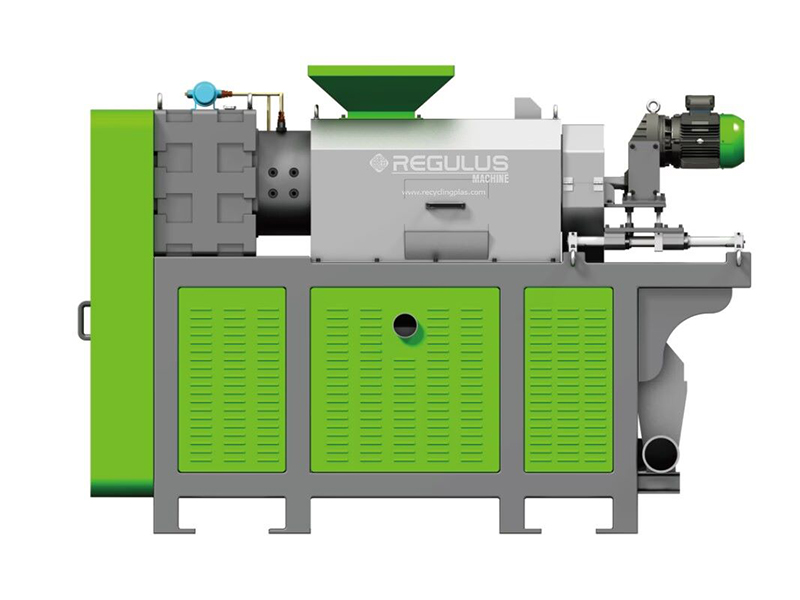

Plastic Squeeze Dryer

The latest solutions for film washing line.

It is used for drying the film, bags. After washing, the film moisture is usually retaining more than 30%. Through this machine, the film moisture will be lowered down to 1-3%.

The machine can increase the quality of the pellets and the efficiency of the extruders.

Model: 250-350kg/h, 450-600kg/h, 700-1000kg/h