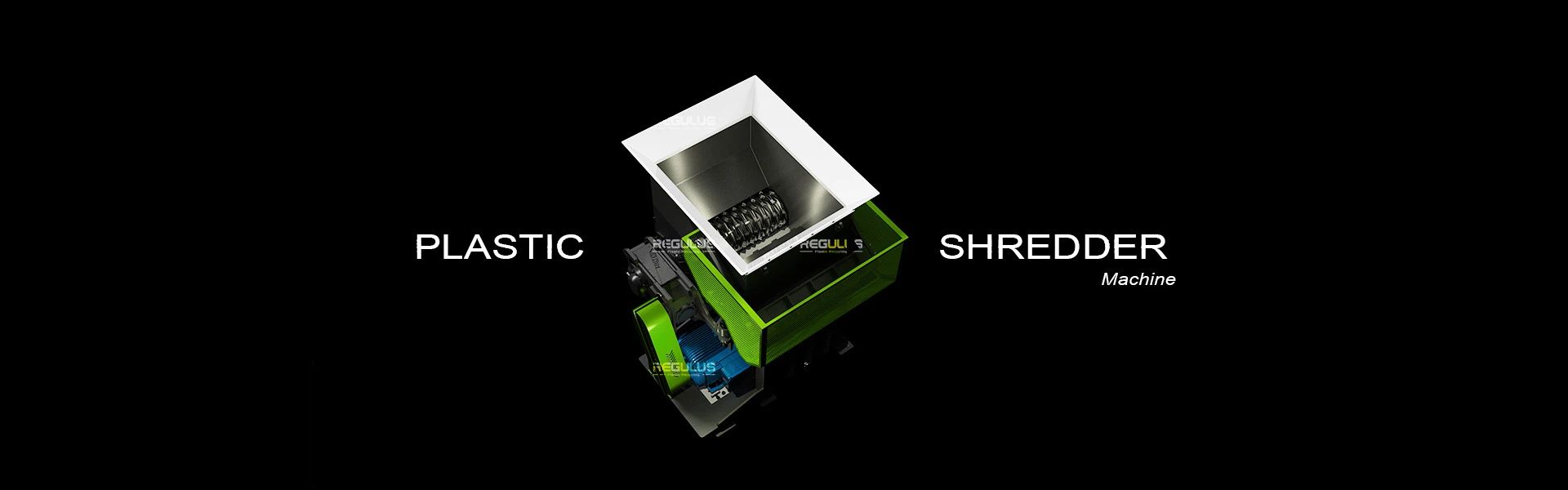

Pre-Shredder Plastic Shredder Machine

What is Plastic Shredder?

The YS series shredder, developed by our factory, represents a new generation of shredding technology that offers exceptional efficiency in shredding a wide range of materials. This advanced shredder is designed to effectively process various substances while ensuring low energy consumption and high output. By providing users with the flexibility to choose from different models based on material size and desired processing capacity, our YS series shredder enables the achievement of the fundamental goal of "limited resources, unlimited recycling."

What Kind of Plastic Can Be Recycled by Plastic Shredder?

The versatility of the YS series shredder makes it suitable for shredding a multitude of challenging materials. It excels in breaking down resilient plastic films, woven bags, ton bags, cables, large and small hollow containers, fibers, paper, wooden pallets, wood, and other non-metallic packaging materials. It is particularly well-suited for applications in the solid waste treatment industry, where stringent requirements on crushing size may not exist.

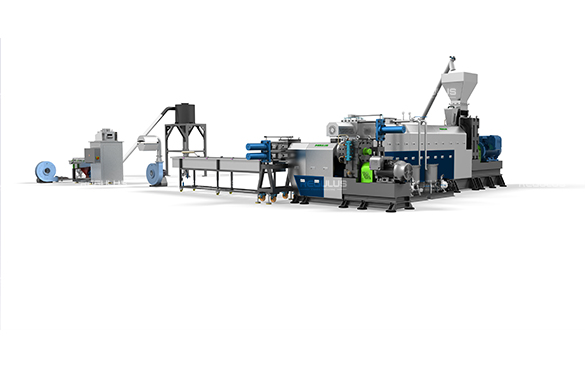

In the realm of plastic recycling, the YS series shredder proves highly effective for the pre-shredding stage of various baled or bundled agricultural films, big bags, and similar materials. It plays a vital role in baled film type recycling solutions, offering efficient and reliable processing at the forefront of the workflow.

Designed for materials with large sediment content, it can break up the whole package of materials and cut them into uniform sizes at one time, which is convenient for pre-processing the sediment and reducing the wear and tear of the back-end host.

Its superior performance, low energy consumption, and high output make it an indispensable tool for efficient and sustainable processing. By choosing the YS series shredder, businesses can optimize their operations and contribute to a circular economy by promoting the recycling and reuse of valuable resources.

What Kind Features of Plastic Shredder?

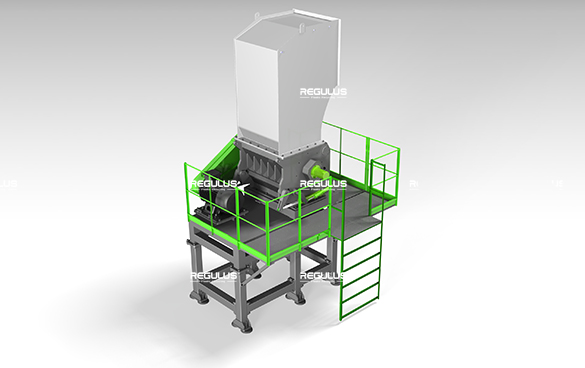

① Driven by a planetary reducer: The shredder is equipped with a planetary reducer, which offers the dual advantages of high torque and a compact installation size. This feature ensures the shredder operates with excellent power and efficiency.

② Innovative pre-shredder design: The pre-shredder component consists of a moving cutter disc and a fixed cutter, working in tandem to efficiently shred materials. The cutter head comprises a base shaft and multiple square moving cutter blocks, securely fixed onto the base shaft with screws. As the base shaft rotates, the moving cutter blocks also rotate, creating a powerful cutting action. The frame of the shredder features an array of static knives that assist in the shredding process.

③ Versatile shredding capabilities: Unlike traditional shredders and crushers that can only operate in a forward rotation, the YS series pre-shredder introduces a unique design and installation structure for its moving knife. This design enables the pre-shredder to perform both forward shredding and reverse shredding of materials. When the main machine experiences heavy loads, the pre-shredder can effectively shred and crush materials in reverse, significantly improving crushing efficiency.

④ PLC-controlled automatic positive and negative crushing: The pre-shredder incorporates a specially designed PLC program, allowing for automatic control of the positive and negative crushing operations. This advanced control system enhances operational convenience and optimizes the shredding process.

⑤ Auxiliary hydraulic pressing arm: The YS series pre-shredder is equipped with its own auxiliary hydraulic pressing arm. This feature plays a crucial role in enhancing crushing efficiency. The hydraulic pressing arm exerts pressure on the materials being shredded, facilitating better material feed and promoting efficient shredding performance.

What Product Capacity Does the Plastic Shredder Do?

| Model | YS1000 | YS1200 | YS1600 |

| Motor Power | 55kw | 75 kw or 90 kw | 110kw or 132kw |

| Qty of Rotor blades | 20 pcs | 24 or 36 pcs | |

| size of Rotor blades | 105*50 | 105*50 | 105*50 |

| Qty of Fixed blades | 10 pcs | 12 pcs | 16 pcs |

| Materials of blades | Cr12MoV/SKDII/D2 | Cr12MoV/SKDII/D2 | Cr12MoV/SKDII/D2 |

| Speed | 17-26 rpm | 17-26 rpm | 17-26 rpm |

| Diameter of Rotor | 500 mm | 600 mm | 600 or 750mm |

| shredding room size | 1000*500 mm | 1200*600 mm | 1600*600 or 750 |

| Hydraulic motor power | 2.2 kw | 2.2 kw | 3 kw |

| Output | 0.8T-1.5T/hr | 1T-1.5T/hr | 1.5T-2.5T/hr |

| Dimension L/W/H | 3800*1100*2600 mm | 4200*1250*2600 mm | 4800*1400*2800 mm |

| Weight | 4800 kg | 7000 kg | 10000kg |