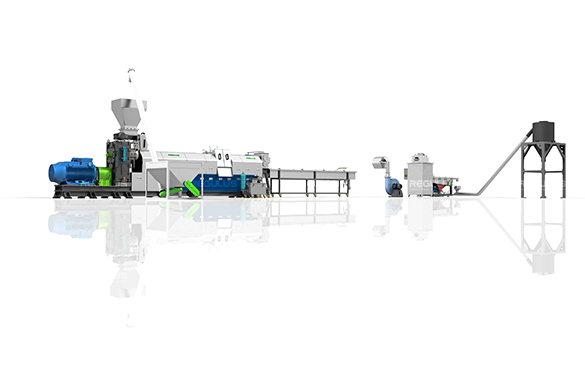

Single Shaft Shredder

Single Shaft Shredder

It is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, fiber, rubber, organic waste and a wide variety of materials. As per our customers’ requirements, such as the input size of the material, capacity and the final output size etc., we could work out a suitable proposal for our clients. After being shredded by the machine, the output material could be used directly or go into the next step of size reduction. With the function of Siemens microcomputer control system, it is possible to control automatically start, stop, automatic reverse sensors to protect the machine against over loading and jamming.

Product Application

| 1. Plastic film/woven bag/PET bottle/plastic barrels/plastic pipe/plastic boards | 2. Paper/cardboard boxes |

| 3. Hard plastic:Plastic lump/purgings/fiber/engineering plastic ABS, PC, PPS | 4. Wood/timber/tree root/wood pallets |

| 5. TV shell/washing machine shell/refrigerator body shell/circuit boards | 6. Light metal |

| 7. Solid waste: industrial waste, domestic waste, medical waste | 8. Cable |

Final Products

Product Features

| 1. Rotor: | Various rotor configurations available for processing a wide range of materials. Blades are made from hardened DC53 steel; the blades can be turned 4 times before changing. |

| 2. Gearbox: | Water cooled gearbox guards against overloading. Hardened teeth on the reducer. |

| 3. Shock Absorber: | Absorbs vibrations caused by the shredding of the material. This protects the machine and its various parts from damage. |

| 4. RAM: | The hydraulic ram pushes material against the rotor. |

| 5. Bearing Seat: | Protective bearing covers to avoid foreign contamination entering the bearing housing. Grease points to release oil at intervals to increase service life. |

| 6. Screen: | Various screen sizes. |

| 7. Hydraulic Station: | The ram pressure and timing can be adjusted to suit different materials. |

| 8. CE certified: | Safety devices in line with European CE certification |

Main Technical Parameters

I.WT22/40 Series Single Shaft Shredder:

| Model | WT2260 | WT4080 | WT40100 | WT40120 | WT40150 |

| Cutting Chamber C/D(mm) | 850*600 | 1300*800 |

1300*1000 | 1400*1200 | 1400*1400 |

| Rotor Diameter (mm) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Main Shaft Speed (r/min) | 83 | 83 | 83 | 83 | 83 |

| Screen Mesh (mm) | φ40 |

φ50 | φ60 | φ60 | φ60 |

| Rotor-knives (pcs) | 28 | 40 | 48 | 61 | 78 |

| Main Motor Power (kw) | 22 | 37-45 | 45-55 | 75 | 75-90 |

| Hydraulic Motor Power (kw) | 2.2 | 3 | 3 | 5.5 | 7.5 |

II. WT48 Series Single Shaft Shredder:

| Model | WT4080 | WT40100 | WT40120 |

| Cutting Chamber C/D(mm) | 1300*1000 | 1400*1200 | 1400*1500 |

| Rotor Diameter (mm) | φ480 | φ480 | φ480 |

| Main Shaft Speed (r/min) | 74 | 74 | 74 |

| Screen Mesh (mm) | φ60 | φ60 | φ60 |

| Rotor-knives (pcs) | 48 | 61 | 78 |

| Main Motor Power (kw) | 45-55 | 75 | 75-90 |

| Hydraulic Motor Power (kw) | 3 | 5.5 | 7.5 |

III. WTP40 Series Pipe-Single Shaft Shredder:

| Model | WTP2260 | WTP4080 | WTP40100 | WTP40120 | WTP40150 |

| Cutting Chamber C/D(mm) | 600*600 | 800*800 | 1000*1000 | 1200*1200 | 1500*1500 |

| Rotor Diameter (mm) | φ220 | φ400 | φ400 | φ400 | φ400 |

| Main Shaft Speed (r/min) | 83 | 83 | 83 | 83 | 83 |

| Screen Mesh (mm) | φ40 | φ50 | φ60 | φ60 | φ60 |

| Rotor-knives (pcs) | 28 | 42 | 51 | 63 | 78 |

| Main Motor Power (kw) | 22 | 37 | 45 | 55 | 75 |

| Hydraulic Motor Power (kw) | 2.2 | 3 | 3 | 5.5 | 7.5 |

Videos for the Single Shaft Shredder:

Write your message here and send it to us