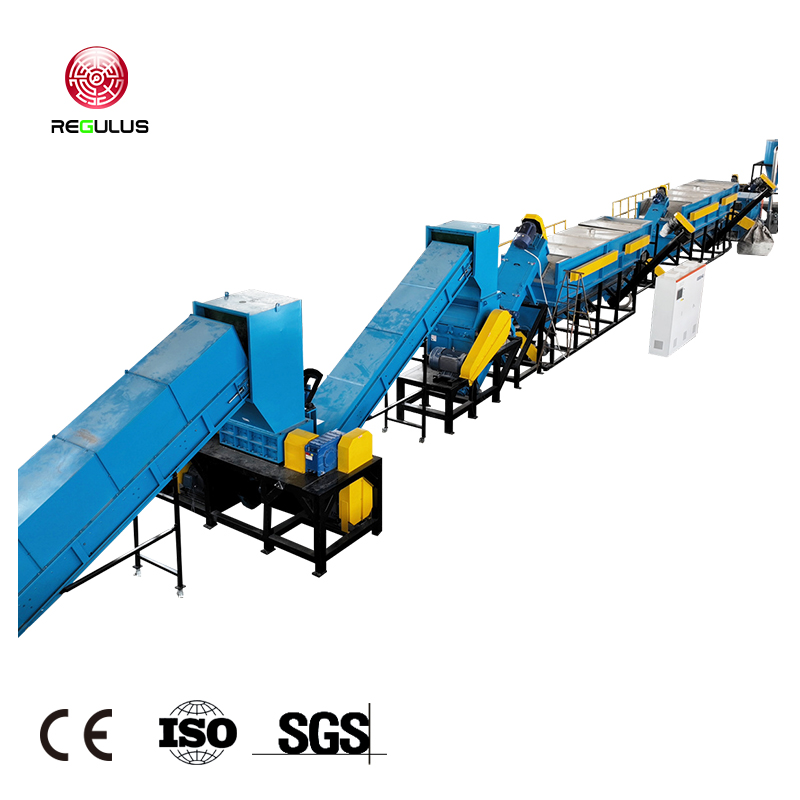

PE PP Washing and Recycling Line

PE PP Washing and Recycling Line

PP, PE film washing and recycling line is mainly consist of the following machines: Belt conveyor, metal detector , crusher, screw feeder, high speed friction washer, floating washer, dewatering machine, drier, storage silo and control cabinet.

The recycled material can be used for directly sale ,pelletizing,injection molding,extrusion and film blowing.

Products Video:

Application:

Mainly in Plastic PE, PP, LLDPE, HDPE, LDPE.

Product Specifications:

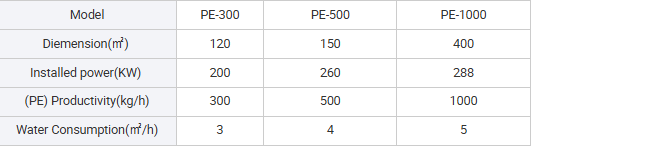

PE/PP Plastic Washing Recycling Line 300-1000kg/h

Working Process:

crusher→Friction washer→Washer tank→Friction washer→Washer tank→Dehydration→Dryer→Bagging

used for crushing, washing, drying waste plastics PE.LDPE,LLDPE,HDPE and PP. It includes plastic film, waste agricultural film, industrial packaging fim, woven bags, ton bags

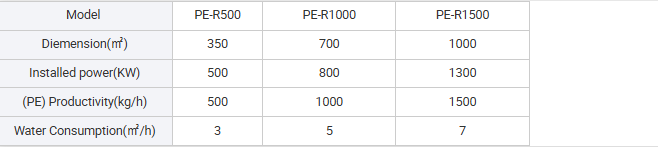

PE Film/ PP Woven Ton Bag Washing Recycling Line 500-1500kg/h

Working Process:

Bales guillotine→Pre-washer→Sorting platform→Shredder→Crusher→Friction washer→Washer tank→Friction washer→Washer tank→Squeeze pelletizer→Silo→Extruder→Pelletizer→Dehydration→Vibrating screen

→Silo→Bagging

used for washing, granulating recycling waste soft plastic PE HDPE LDPE LLDPE film,bags PP ton bags,woven bags,film

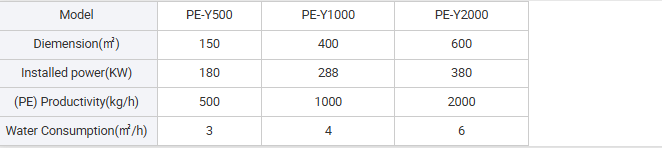

PE/PP Hard Plastic Washing Recycling Line 500-2000kg/h

Working Process:

sorting platform→shredder→crusher→friction washer→washer tank→friction washer→washer tank→dehydration

→dryer→label separation→color sorting→bagging

PP/PE hard material waste plastics. For example, milk bottles, laundry detergent bottles,engine oil bottles,PE PP plastic containers,trays,tubes,pipes,bottle caps, etc.

Features at a glance:

Crusher

Function: crushing the material into flakes

By crushing, large-sized raw materials are divided into relatively uniform small-sized raw materials.

Friction Washer:

Function: Friction washing the material and loading up it

The friction washer is high rotating speed cleaning equipment. The plastic runs against each other at high speed geeting rid of

hard to remove contamination.

The friction washer is high rotating speed cleaning equipment. The plastic runs against each other at high speed geeting rid of

hard to remove contamination.

Floating Washing Tank

Function: Floating washing separate the sand, soil and other dirtie

In the washing tank, the plastic PP and PE will float, and heavier contamination such as dirt , sand , glass ,metals , other plastics will sink .

Screw Loader

Function: PET flakes conveying

Centrifugal Dewatering Machine:

The machine uses centrifugal force to remove a large portion of water within the plastic before moving forward onto the therma dryers

Write your message here and send it to us