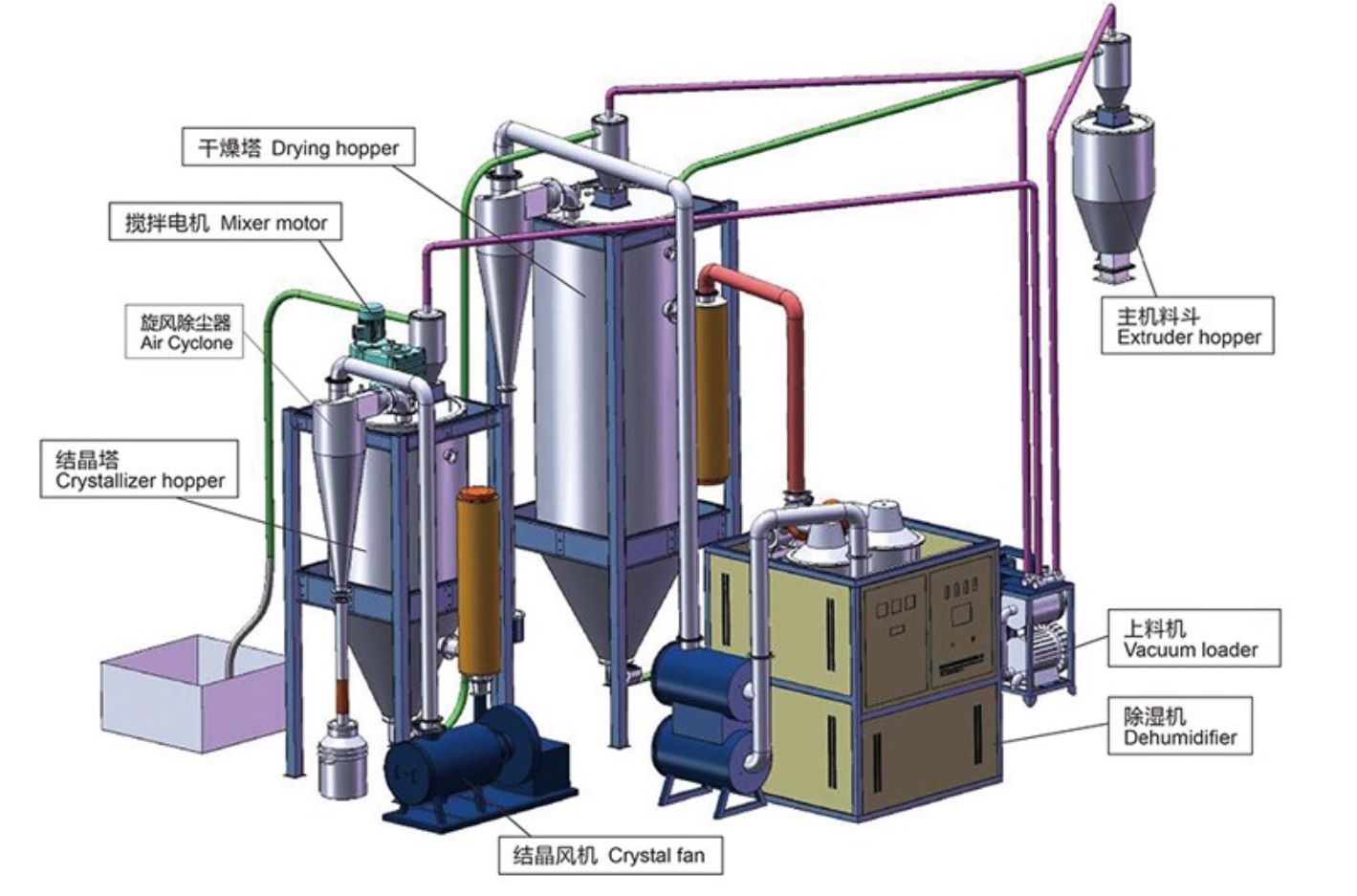

PA PC PET Crystallization Dehumidification Drying Equipment

Crystallization Dehumidification Drying Equipment

The Dehumidifying dryer combine dehumidifying and drying system into a single unit. This machine has many applications in processing plastic materials, such as PA, PC, PBT, PET.

It is special for Engineering plastics with strong hygroscopicity, such as PA.

Features:

1 Compact in size for easy of movement and space saving.

2 The machine is equipped with PLC control, it is used to ensure the drying of plastic granules

and the regeneration process of molecular sieve, the process is carried out automatically and continuously according to the program set in the computer.

Technical Parameters:

| Output(kg/h) | Effective Drying Volume(m³) | Heating Drying(KW) | Effective Crystal Volume(m³) | Crystal Heating(KW) | Drying Pneumatic Power(KW) | Feeding System(KW) | Reproducing Heat(KW) |

| 100 | 0.65 | 24 | 0.5 | 24 | 7.5 | 2.2 | 20 |

| 200 | 1.0 | 24 | 0.9 | 24 | 7.5 | 4 | 20 |

| 300 | 2.7 | 36 | 1.2 | 27 | 12.5 | 5.5 | 24 |

| 400 | 3.6 | 36 | 1.6 | 27 | 12.5 | 5.5 | 24 |

| 500 | 4.5 | 45 | 2.0 | 36 | 18 | 5.5 | 30 |

| 800 | 7.2 | 45 | 1.6 | 36 | 25 | 5.5 | 30 |

Working Principle:

For hygroscopic plastic, moisture will enter the plastic pellets, and the formation of molecular bonds. These pellets can only remove moisture with moist hot air.

The “Dehumidifyingdryer” provides dry air to the silo, it is high to dehumidify by molecular adsorption on water molecular sieve, reduce the dew point of the air, and then blowing into the heating hopper, this time the air flow has three major elements for drying plastic: current speed, temperature and low dew point. When the air flow passes through the hopper, it can evaporate and take away the water on the surface of the plastic, and also remove the crystal water inside the plastic molecule. Finally, the requirement of the plastic processing is ensured.