Plastic pollution has become a pressing global issue, with millions of tons of plastic waste ending up in our oceans, landfills, and natural environments every year. Addressing this problem requires innovative solutions, and one such solution is the PPPE washing recycling line.

The PP PE washing recycling line is a comprehensive system designed to recycle and reuse post-consumer plastic materials, specifically polypropylene (PP) and polyethylene (PE). These types of plastics are commonly used in packaging, bottles, and various consumer products, making them significant contributors to plastic waste.

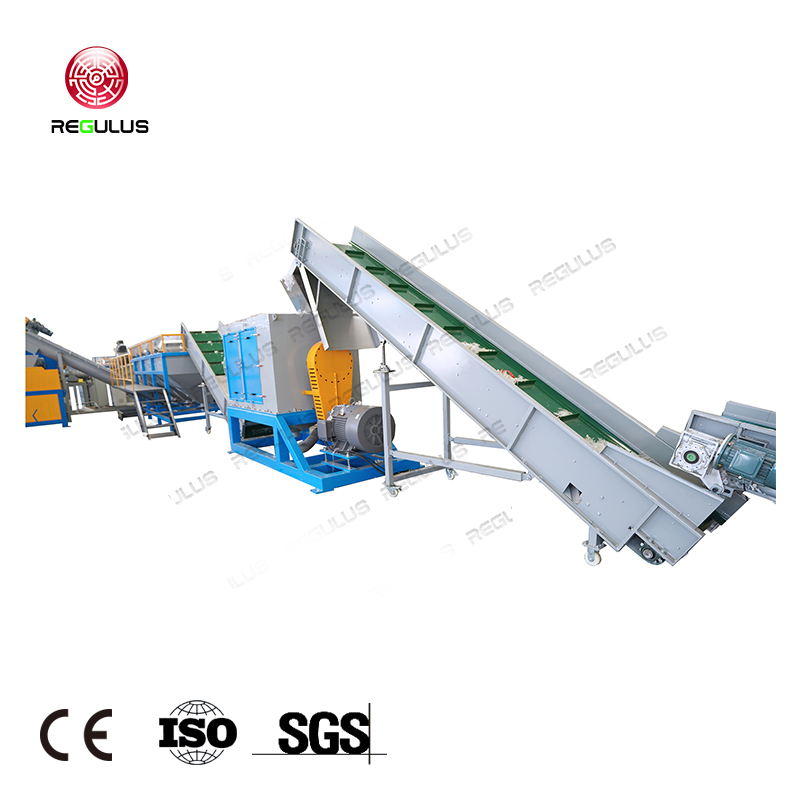

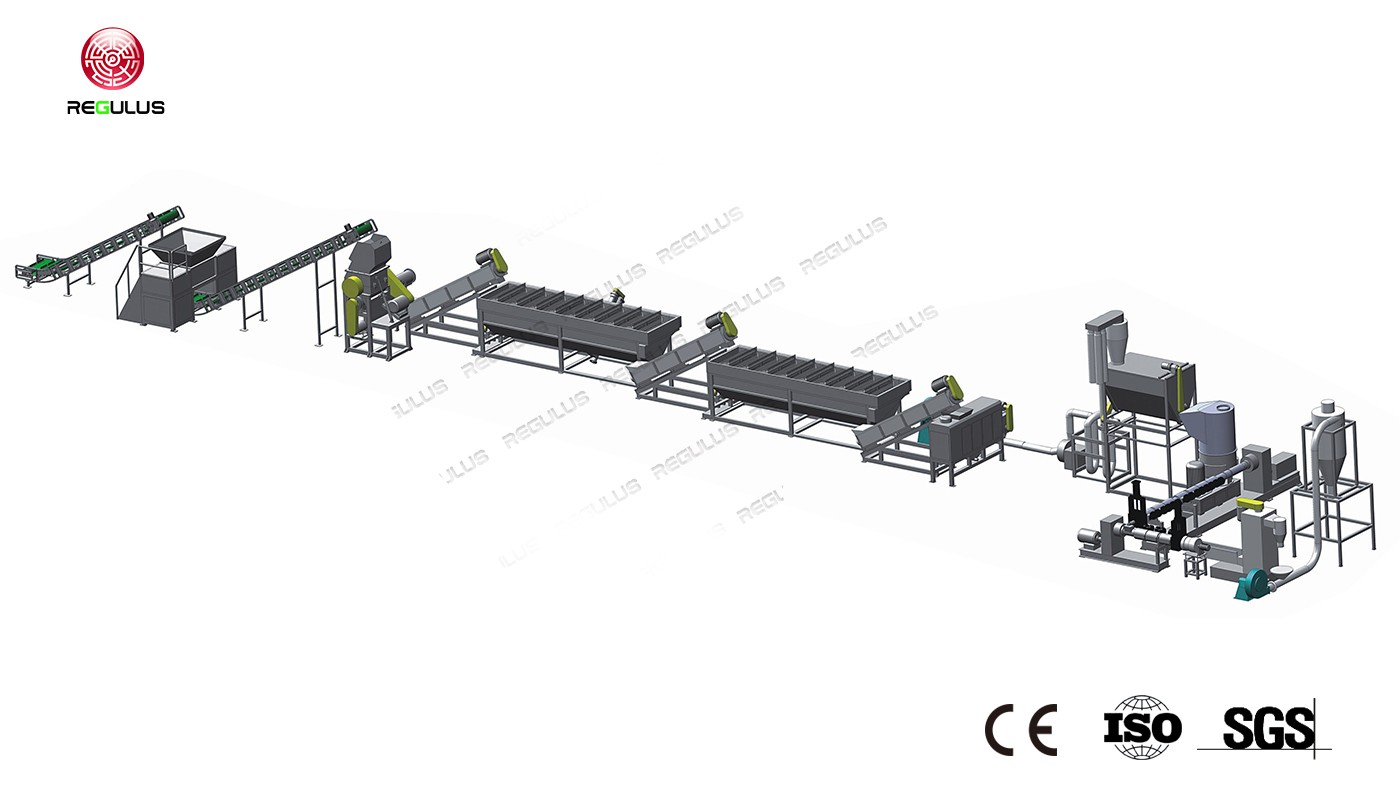

The recycling line consists of several key components that work in harmony to process and transform plastic waste into reusable materials. The first step involves a sorting mechanism that separates different types of plastics based on their composition and color. This ensures a homogeneous feedstock for subsequent stages of the recycling process.

Next, the plastic waste is subjected to a thorough washing process. This involves a series of cleaning steps, such as friction washing, hot water washing, and chemical treatment, to remove contaminants such as dirt, labels, and adhesives. The washing process plays a crucial role in producing high-quality recycled plastic materials.

Once cleaned, the plastic waste is mechanically shredded into smaller pieces and then passed through a series of equipment, including a granulator, friction washer, and centrifugal dryer. These machines help break down the plastic into granules and remove excess moisture, preparing the material for the final stage of the recycling line.

The granulated plastic is then melted and extruded into uniform pellets, which can be used as raw material for various industries. These recycled pellets possess properties similar to virgin plastic, making them suitable for manufacturing new products such as plastic containers, pipes, and packaging materials.

The benefits of implementing a PPPE washing recycling line are numerous. Firstly, it significantly reduces the amount of plastic waste that ends up in landfills or pollutes our environment. By recycling plastic materials, we can conserve valuable resources and minimize the need for new plastic production.

Furthermore, the use of recycled plastic reduces carbon emissions and energy consumption associated with manufacturing processes. Recycling plastic requires less energy than producing virgin plastic from fossil fuels, contributing to a more sustainable and environmentally friendly approach.

Moreover, the PPPE washing recycling line helps create a circular economy for plastic, where materials are reused and recycled instead of discarded. This reduces the demand for new plastic production, conserves resources, and minimizes the negative impact of plastic waste on ecosystems.

In conclusion, the PPPE washing recycling line offers an effective solution to tackle the global plastic waste crisis. By implementing this comprehensive recycling system, we can transform post-consumer plastic waste into valuable resources, reduce environmental pollution, and promote a sustainable approach to plastic consumption. Embracing such innovative recycling technologies is crucial for a cleaner and greener future.

Post time: Aug-01-2023