Plastic recycling has become an essential practice in today's world due to the increasing concerns about environmental sustainability. Recycling plastic waste helps reduce pollution, conserve natural resources, and decrease the amount of plastic ending up in landfills or oceans. In the plastic recycling process, one crucial step is drying the plastic waste before further processing or reusing it. This is where a plastic recycling squeezing dryer machine plays a vital role.

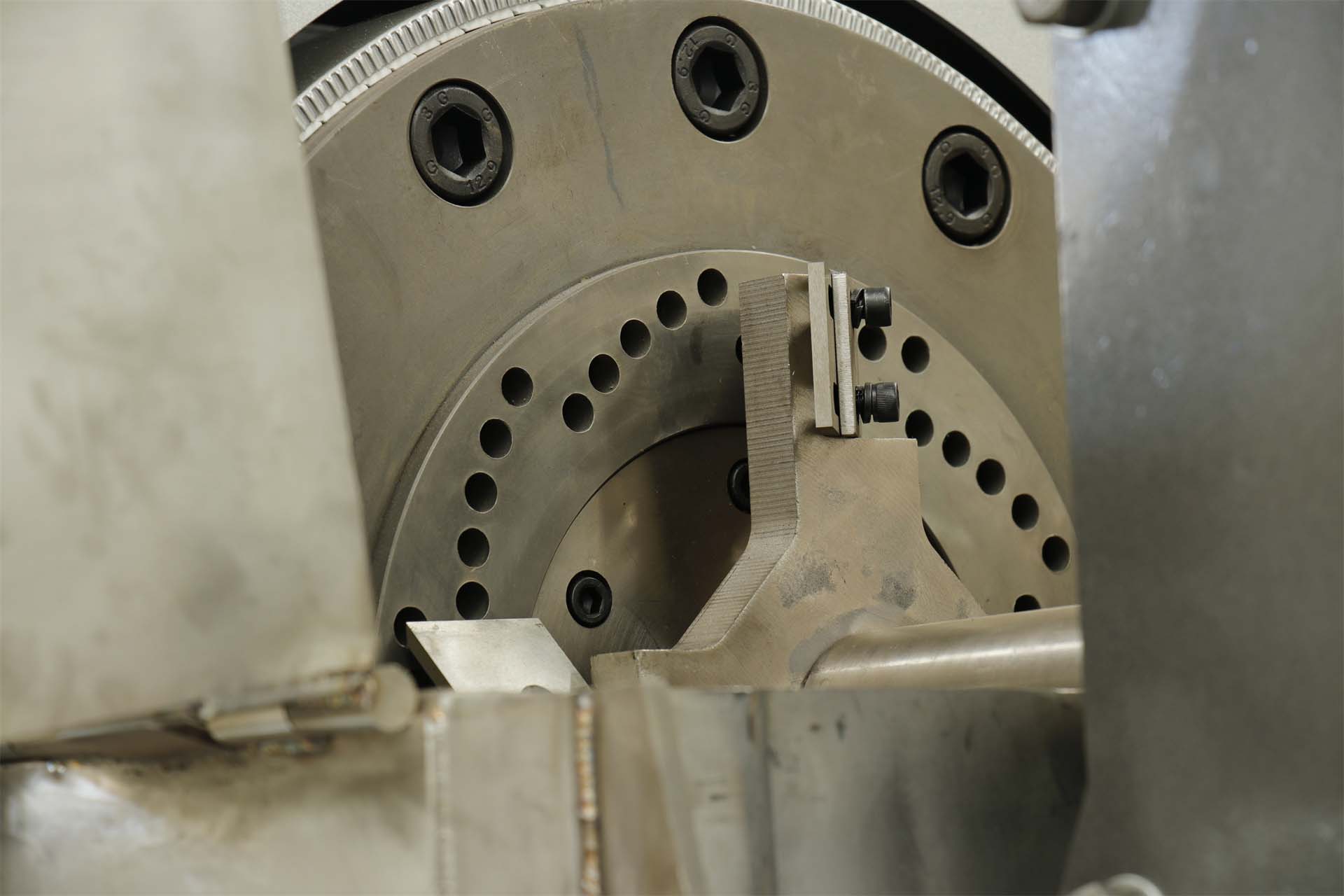

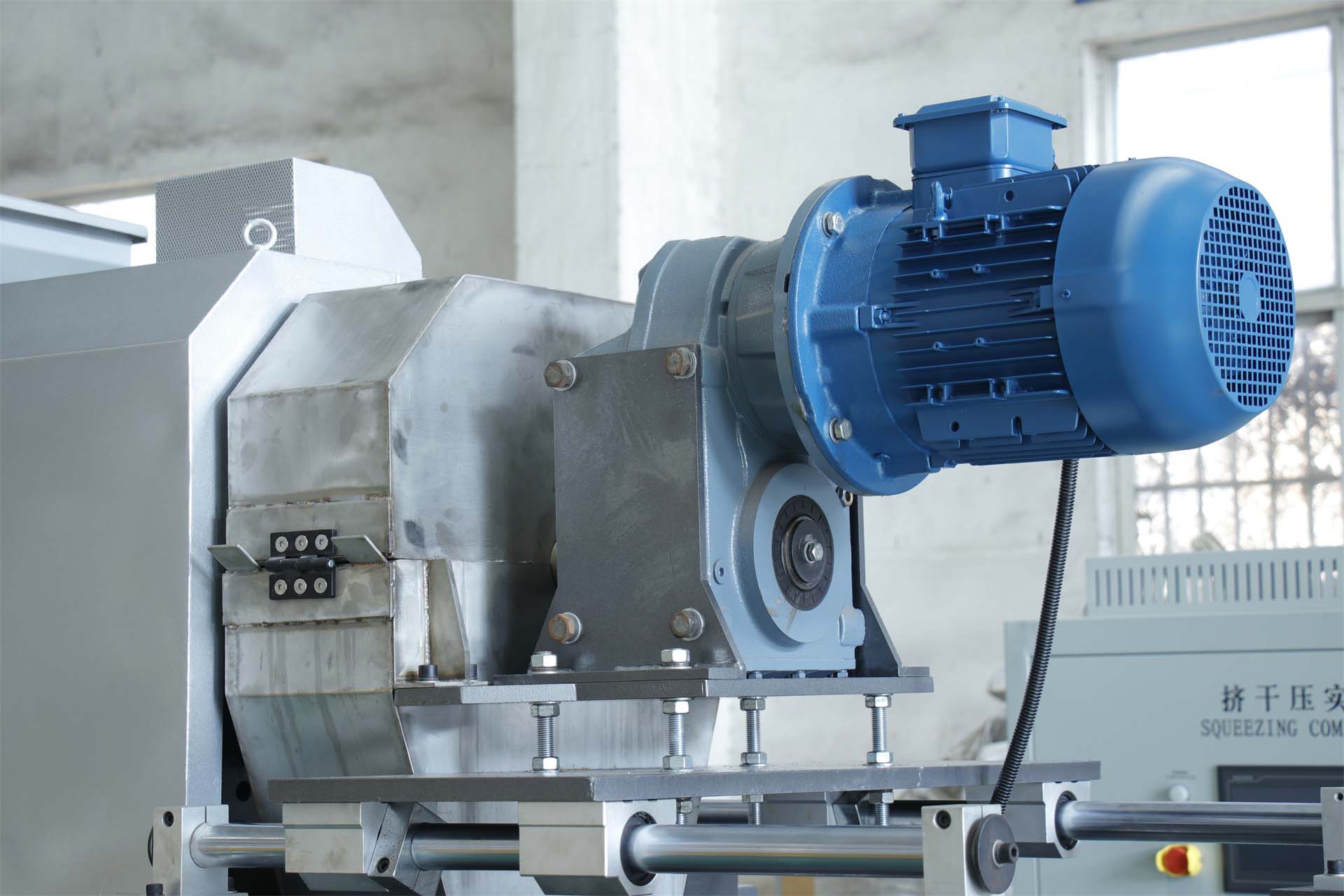

The plastic recycling squeezing dryer machine employs a combination of mechanical and thermal processes to achieve efficient drying. The machine consists of a hopper or feed inlet where the wet plastic waste is introduced. The plastic waste is then transferred into a screw conveyor or auger mechanism, which applies pressure to the material, forcing out the moisture.

The squeezing action of the machine's screw conveyor compresses the plastic waste and creates a high-pressure environment, expelling the water or other liquid contents. Some models may also incorporate heating elements or heat transfer mechanisms to accelerate the drying process. The heat helps evaporate the moisture, and the resulting water vapor is typically vented out of the machine.

Plastic recycling squeezing dryer machines are designed to handle various types of plastic waste, including PET (polyethylene terephthalate), HDPE (high-density polyethylene), LDPE (low-density polyethylene), PVC (polyvinyl chloride), and more. The machines can accommodate different forms of plastic waste, such as bottles, containers, films, and even shredded plastic materials.

Benefits of using a plastic recycling squeezing dryer machine include:

Improved efficiency: By reducing the moisture content, the machine optimizes the subsequent recycling processes, such as shredding, extrusion, or pelletizing. Dry plastic waste is easier to handle and has better flow characteristics, leading to increased productivity and reduced energy consumption.

Enhanced quality of recycled plastic: Moisture-free plastic has better physical properties, ensuring that the recycled plastic meets the desired quality standards. It can be used in various applications, including manufacturing new plastic products or as raw material in other industries.

Environmental impact: By effectively drying plastic waste, the recycling squeezing dryer machine contributes to reducing the overall environmental impact of plastic recycling. It minimizes the need for additional drying steps, conserves energy, and promotes a more sustainable approach to plastic waste management.

Versatility: The machine can handle different types and forms of plastic waste, offering flexibility in recycling operations. It can process various sizes and shapes of plastic materials, adapting to the specific requirements of different recycling facilities.

In conclusion, a plastic recycling squeezing dryer machine is an integral part of the plastic recycling process. By efficiently removing moisture from plastic waste, it improves the quality of recycled plastic, enhances productivity, and supports sustainable waste management practices. With the growing emphasis on environmental conservation, the use of these machines is crucial in promoting a circular economy and reducing the environmental impact of plastic waste.

Post time: Aug-01-2023