In industries where moisture removal is paramount, the series squeezing dryer has emerged as a groundbreaking solution. This advanced drying equipment offers efficient and cost-effective methods for extracting moisture from various materials. By utilizing a series of squeezing mechanisms, this dryer ensures thorough and uniform drying, significantly improving the quality and usability of the end product. In this article, we will delve into the workings, benefits, and applications of the series squeezing dryer.

Operating Principle

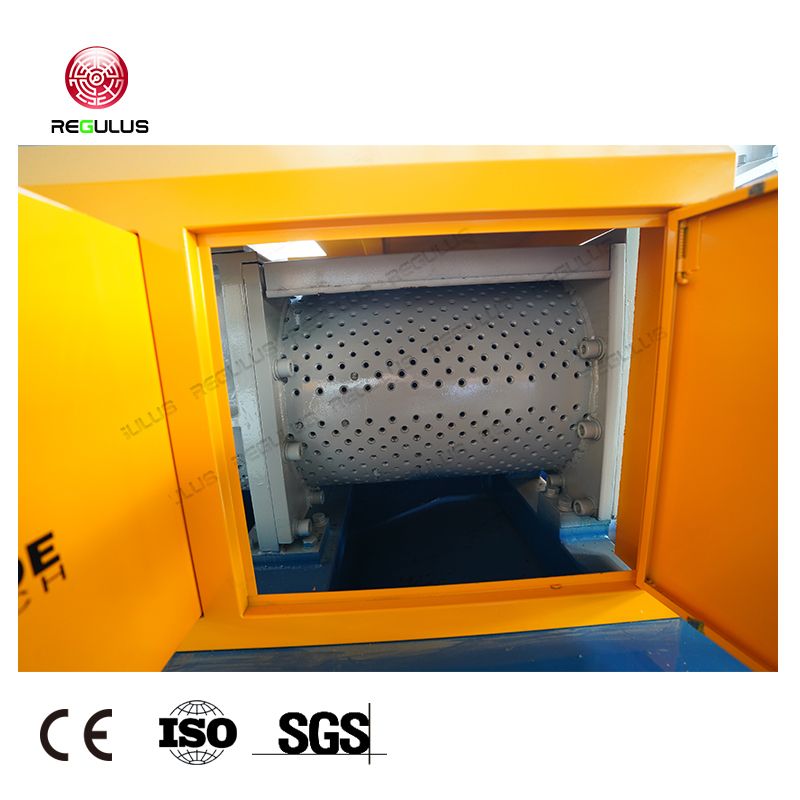

The series squeezing dryer employs a series of squeezing rollers, which gradually compress the wet material as it passes through the conveyor belt system. The squeezing rollers exert pressure on the material, effectively extracting moisture from its structure. This squeezing action releases the moisture, which is then collected and removed from the dryer, while the drier material continues through the system. The squeezing process is repeated in a series of stages to ensure thorough drying and optimal moisture removal.

Key Advantages

Enhanced Moisture Removal: The series squeezing dryer excels at removing moisture from a wide range of materials. Its unique squeezing mechanism ensures efficient and thorough drying, leading to a significant reduction in moisture content. This results in improved product quality and extended shelf life.

Uniform Drying: Unlike traditional drying methods, the series squeezing dryer provides uniform drying throughout the material. The squeezing action eliminates moisture from all parts of the material, preventing uneven drying and ensuring consistency in the final product.

Energy Efficiency: The dryer's design optimizes energy consumption. The squeezing process requires less energy compared to other drying techniques, resulting in cost savings and reduced environmental impact.

Versatility: The series squeezing dryer can handle various materials, including fruits, vegetables, grains, textiles, and more. Its adaptability makes it suitable for industries such as food processing, agriculture, pharmaceuticals, and textiles.

Preservation of Nutrients and Product Integrity: The gentle squeezing action of the dryer helps preserve the nutritional value, texture, and overall integrity of the dried material.This is particularly beneficial for the food industry, where maintaining product quality is crucial.

Applications

The series squeezing dryer finds applications in numerous industries, including:

Food Processing: It is used for drying fruits, vegetables, herbs, and other food products, preserving their quality, flavor, and nutritional value.

Agriculture: The dryer is employed for drying crops, grains, seeds, and other agricultural produce, ensuring reduced spoilage and improved storage life.

Textile Industry: It is utilized for drying textiles, fabrics, and garments, removing excess moisture and facilitating subsequent processes like dyeing and finishing.

Pharmaceutical Industry: The dryer is employed for drying pharmaceutical powders, granules, and ingredients, ensuring accurate dosage and stability.

Recycling: It is used in recycling processes to remove moisture from recycled materials, such as plastic flakes, ensuring their suitability for further processing.

Conclusion

The series squeezing dryer represents a significant advancement in moisture removal technology. With its efficient squeezing mechanism, uniform drying capabilities, and versatile applications, this drying equipment offers numerous benefits across various industries.By effectively extracting moisture from materials, the series squeezing dryer improves product quality, reduces waste, and enhances overall efficiency.As industries continue to prioritize moisture control, the series squeezing dryer plays a crucial role in meeting their drying needs.

Post time: Aug-02-2023