There is no denying that plastics play an important role in manufacturing and packaging. However, as the world continues to weigh the global environmental impact of plastics many companies are modifying their operations to implement sustainable practices.

PET is the preferred choice for plastic bottles (and other uses) because it is 100% recyclable and highly sustainable. It can be recycled into new products again and again, reducing the waste of resources. This is different from other types of plastics such as polyvinyl chloride (PVC), low-density polyethylene (LDPE), polypropylene (PP), polystyrene(PS), which are used in cling film, disposable plastic bags, food Containers and disposable cups.

PET products can have long life cycles, are easily recycled, and recycled PET is a valuable commodity with the potential to close the loop. Recycled PET can be used to produce PET products, such as: two-dimensional, three-dimensional polyester staple fiber, polyester filament and sheet, etc.

Regulus provides you with a professional PET recycling production line. We offer innovative recycling solutions, which are specifically designed to fit the circular economy.

PET recycling production line description:

1. The whole production line reasonably structured, high degree automation, low electric energy consumption, high capacity, good clean effect, long using life.

2. Final product PET flakes can be used for chemical fiber factory after this line, and used for producing PET strap, no need to do any treatment.

3. Product capacity range is 500-6000 kg/hr.

4. Size of final product can be adjusted according to change crusher screen mesh.

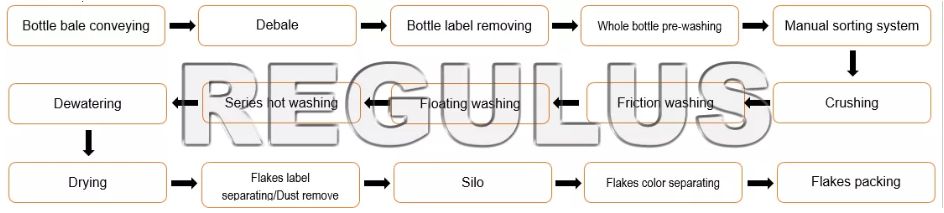

PET recycling production line Working Flow:

Belt conveyor → Bale opener machine → Belt conveyor → Pre-washer (trommel) →Belt conveyor → Mechanical label remover → Manualseparating table → Metal detector →Belt conveyor → Crusher → Screw conveyor → Floating washer →Screw conveyor → Hot washer chamber →Screw conveyor*2 → High speed friction machine → Screw conveyor → Floating washer → Screw conveyor →Floating washer→Screw conveyor → Horizontal dewatering machine → Drying pipe system → Zig zag air classification system → Storage hopper → Control cabinet

For more detailed information, please contact us.

Post time: Aug-01-2023