Advantages:

Simple operation: The structure of the single stage strand cooling granulation line is relatively simple, with a high degree of automation, and is easy to operate and maintain.

High production efficiency: Through optimized design, efficient plastic granule production can be achieved to meet the needs of mass production.

Strong adaptability: The equipment is suitable for granulation of various plastic materials, such as PP, PE, PA, PS, TPU, etc., and can meet the plastic granulation needs of various industries.

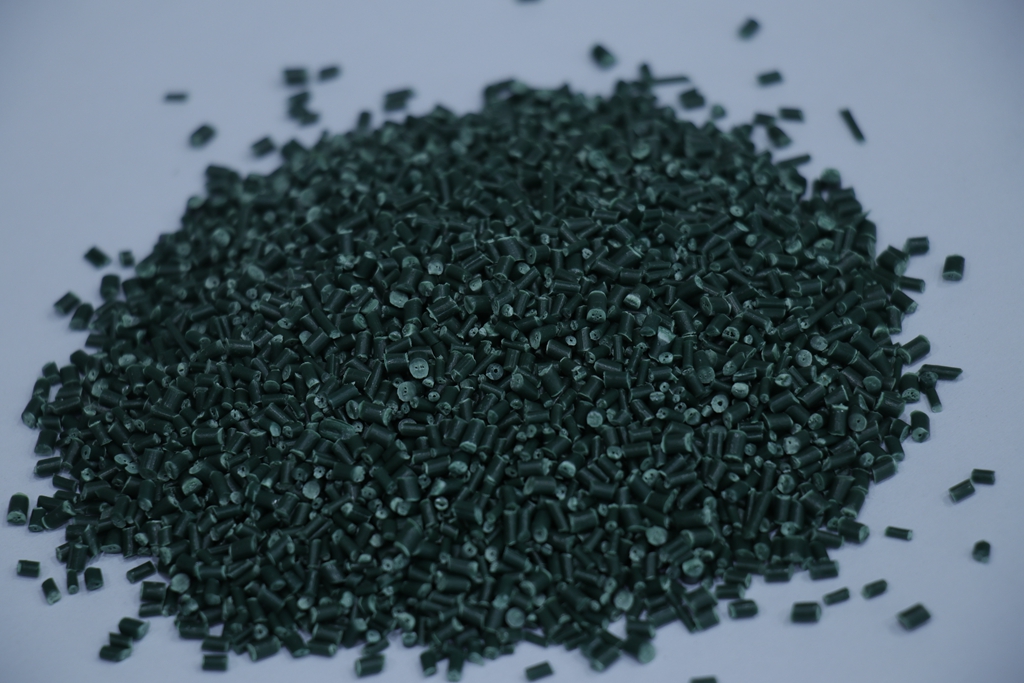

Stable finished product quality: It can achieve better melting and mixing effects, ensuring uniform granulation and high finished product quality.

Main Equipment:

Screw feeder: The screw feeder is responsible for automatically conveying the plastic to the feeder. It ensures that the material enters the production line evenly and continuously through screw conveying, reduces manual handling, and improves production efficiency.

Feeder: The feeder controls the quantitative supply of plastic to ensure that the material entering the extruder is stable and uniform. This ensures uniform melting and plasticization of the plastic during the subsequent granulation process. It can adjust the feed speed according to production needs and improve the flexibility of the production line.

Extruder: The extruder is the core equipment of the granulation line, responsible for heating, melting and extruding the plastic raw materials.

Screen changer: It is used to filter impurities in the molten plastic to ensure the quality of the produced plastic pellets. The equipment can replace the filter without stopping the machine, improving the continuity and efficiency of the production line.

Dehydrator: The function of the dehydrator is to cool and dehydrate the newly extruded plastic strips. Prepare for the subsequent pelletizing process.

Vibrating screen: The vibrating screen is used to separate plastic particles of different sizes to ensure that the particle size is uniform and meets the product specification requirements.

Silo: The silo is used to store plastic particles, which facilitates subsequent packaging or transportation.

Post time: Oct-18-2024