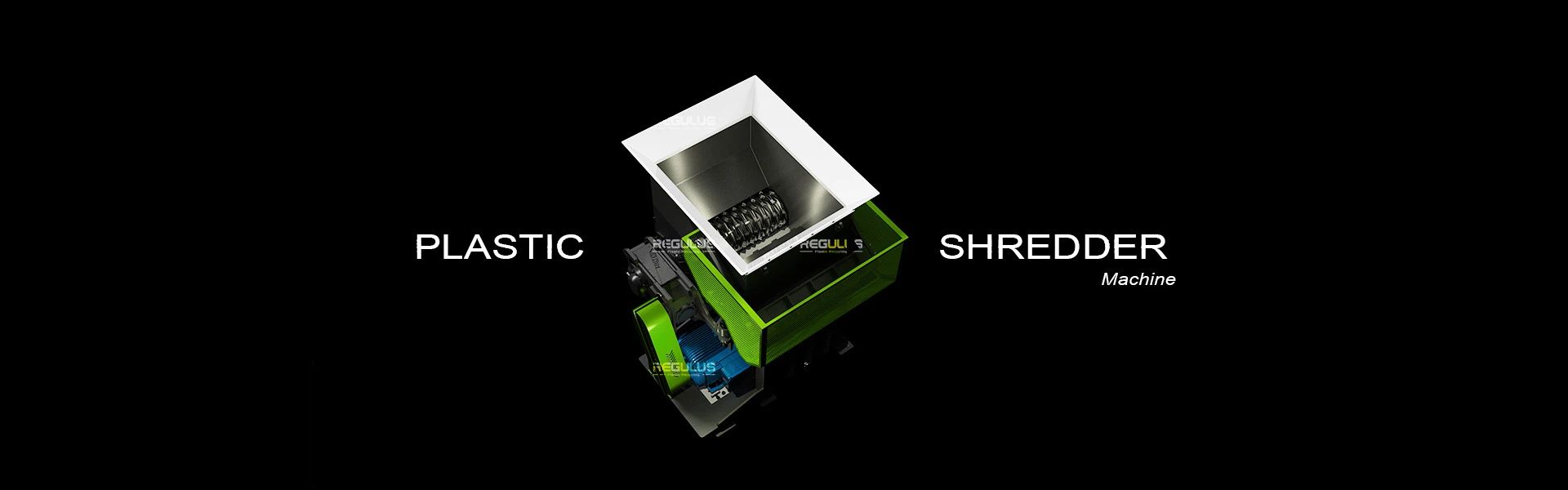

Double Shaft Shredder

Application of Two Shaft Shredder

The two shaft shredders have been designed for a wide array ofapplications and industries, suitable for shredding solid material such asE-waste, metal, wood, plastic, scrap tires, packaging barrel, pallets, etc.

Depending on input material and the following process the shredded material canbe used directly or go into the next step of size reduction. It is widely usedin industry waste recycling, medical recycling, electronic recycling, palletrecycling, municipal solid waste recycling, plastic recycling, tire recycling,paper making industry and etc.

Features of Two Shaft Shredder

The two shaft shredder has two rotors built into the machine that rotate at low speeds, high torque and low noise. Adopt SIEMENS LOGO microcomputer control system with function of start, stop, automatic reverse sensors to protect the machine against over loading and jamming.

Main Technical Parameter of Two Shaft Shredder

1. Small Series of Two Shaft Shredder:

| Model | XYS2130 | XYS2140 | XYS2160 | XYS2180 |

| Cutting chamber C/D(mm) | 300×430 | 410×470 | 610×470 | 910×470 |

| Rotor Diameter (mm) | φ284 | φ284 | φ284 | φ284 |

| Blade quantity (pcs) | 15 | 20 | 30 | 40 |

| Blades thickness (mm) | 20 | 20 | 20 | 20 |

| Main Motor Power (kw) | 7.5 | 7.5 | 5.5+5.5 | 7.5+7.5 |

2. Medium Series of Two Shaft Shredder:

| Model | XYS3280 | XYS32100 | XYS32120 | XYS40100 | XYS40130 | XYS40160 |

| Cutting chamber C/D(mm) | 812×736 | 1012×736 | 1213×736 | 984×948 | 1324×948 | 1624×948 |

| Rotor Diameter (mm) | φ430 | φ430 | φ430 | φ514 | φ514 | φ514 |

| Blade quantity (pcs) | 20 | 25 | 30 | 20 | 26 | 32 |

| Blades thickness (mm) | 40 | 40 | 40 | 50 | 50 | 50 |

| Main Motor Power (kw) | 15+15 | 22+22 | 22+22 | 37+37 | 45+45 | 45+45 |

3. Heavy series of Two shaft shredder:

| Model | XYS50130 | XYS50180 | XYS61180 | XYS61210 |

| Cutting chamber C/D(mm) | 1612×1006 | 1812×1206 | 1812×1490 | 2112×1510 |

| Rotor Diameter (mm) | φ650 | φ650 | φ800 | φ800 |

| Blade quantity (pcs) | 32 | 36 | 24 | 24 |

| Blades thickness (mm) | 50 | 50 | 75 | 75 |

| Main Motor Power (kw) | 55+55 | 55+55 | 75+75 | 90+90 |

The shredder can further adjust the design according to customers' requirements for waste disposal.

Sales Service of Shredder

1. Pre-sale: our REGULUS company give customer the shredder detail technician offer, 24 hours online response.

2. In-sale: our REGULUS company supply the shredder layout, installation, technical support. Running the shredder machine before delivery.

After customer’s acceptance,we arrange the related machine delivery rapidly, provide detailed packing list and related documents for customers' customs clearance.

3. After sales: we arrange our experienced engineer to install the machinery and training the workers for customer in customer factory.

4. We have 24 hours team to support the after-sales service.

5. We have free spare parts with the machine when we deliver the machine.

We supply long-term spare parts for every customer with cost price.

6. We always update the new technology to every customer.

Faq for Our Shredder Machine

1. Which model of shredder can I choose?

Customers tell us their raw material informaton, such as raw material photos, raw material size. And customers tell us what product capacity they need. Our team will recommend customers a suitable model, and offer you the shredder machine price and specifications.

2. Can I have a customized design?

We design and construct each project according to customer's needs.

Customized is based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V50Hz....)

3. What are your office hours?

24 hours online Q&A from Monday to Saturday.

4. Do you have a price catalog?

We are a professional shredder machine manufacturer. We have different models even for same material type recycling machine, suggest to ask price based on real needs(e.g. capacity or your rough budget).